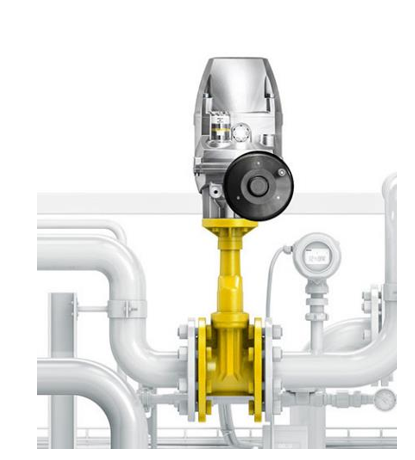

AUMA introduces explosion-proof PROFOX-X actuators

Diana Aoun | May 06, 2024AUMA has launched the PROFOX-X actuators, an explosion-proof addition to its successful PROFOX series, providing safe and precise valve control in potentially hazardous environments. These new actuators extend the benefits of the PROFOX series to applications in explosive atmospheres, meeting the requirements of modern plant automation.

With ATEX and IECEx certifications for the highest gas group IIC T4, including hydrogen, the PROFOX-X actuators ensure safe operation in these environments. The series includes multi-turn, part-turn and linear actuators, catering to various valve types in lower torque and thrust ranges, ideal for compact spaces such as skid installations.

Source: AUMA

Source: AUMA

Maintaining the PROFOX line's focus on energy efficiency, the PROFOX-X series minimizes its carbon footprint while maintaining superior quality, wide temperature tolerance and corrosion protection for reliability and longevity in harsh conditions.

The PROFOX smart actuators support both OPEN-CLOSE duty and modulating applications, with adjustable motor speeds for precise positioning and soft start/stop functionalities to prolong valve service life. Fieldbus and industrial Ethernet communication options ensure seamless integration with host systems, while embedded data logging facilitates advanced diagnostics and predictive maintenance through CORALINK, AUMA's digital ecosystem.

In addition, installation and commissioning are streamlined with a user-friendly app, saving time and resources. The FOX-EYE LED and position indicator on the housing provide clear actuator status updates, even from a distance. AUMA's PROFOX-X actuators represent a sophisticated solution for industries requiring both safety and efficiency in valve control systems.