AI detects defects in wind turbine blades

S. Himmelstein | April 06, 2021The time penalty and occupational hazards associated with manual inspection of wind turbine blades can be eliminated by use of a new artificial intelligence (AI)-based tool for defect detection.

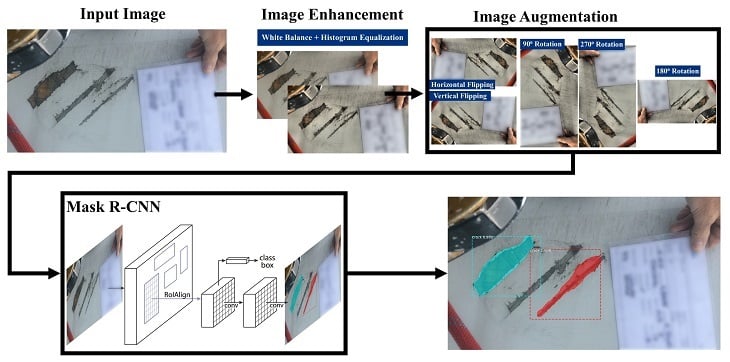

The system developed by engineers in the U.K. has been trained to classify defects by type, such as crack, erosion or void, by analysis of images and videos. The method applies image enhancement and augmentation methods in conjunction with the Mask R-CNN deep learning object detection algorithm to highlight and label defect areas.

The proposed image enhanced Mask R-CNN pipeline. Source: Jason Watkins et al.

The proposed image enhanced Mask R-CNN pipeline. Source: Jason Watkins et al.

When applied to the evaluation of 223 new images, the proposed tool achieved an 85% test accuracy in recognizing and classifying wind turbine blade defects. The images are pre-processed to enhance the AI-based detection process and research is ongoing to further boost accuracy with improvements to pre-processing the images and extending the AI algorithm described in the Journal of Imaging.

The researchers from Loughborough University and Railston & Co. Ltd. are also developing methods for using the system with drone inspections, training the system to detect the severity of defects and evaluating its performance on other surfaces.