A basic introduction to heat exchangers

Temitayo Oketola | September 20, 2023Heat exchangers are central in modern industry, serving as essential components in chemical processing, energy production, automotive systems and HVAC applications. These devices enable controlled heat transfer between different fluids at different temperatures while keeping them from mixing with each other.

However, while seemingly simple in operation, various types of heat exchangers exist today, each with unique characteristics to cater to diverse industrial needs. Knowledge of these types of heat exchangers and the underlying principles that govern their desirable operation is vital for engineers and technicians.

Figure 1: Heat exchangers are central in modern industry, serving as essential components in chemical processing, energy production, automotive systems, and HVAC applications. Source: Surasak/Adobe Stock

Figure 1: Heat exchangers are central in modern industry, serving as essential components in chemical processing, energy production, automotive systems, and HVAC applications. Source: Surasak/Adobe Stock

Basic operating principle of heat exchangers

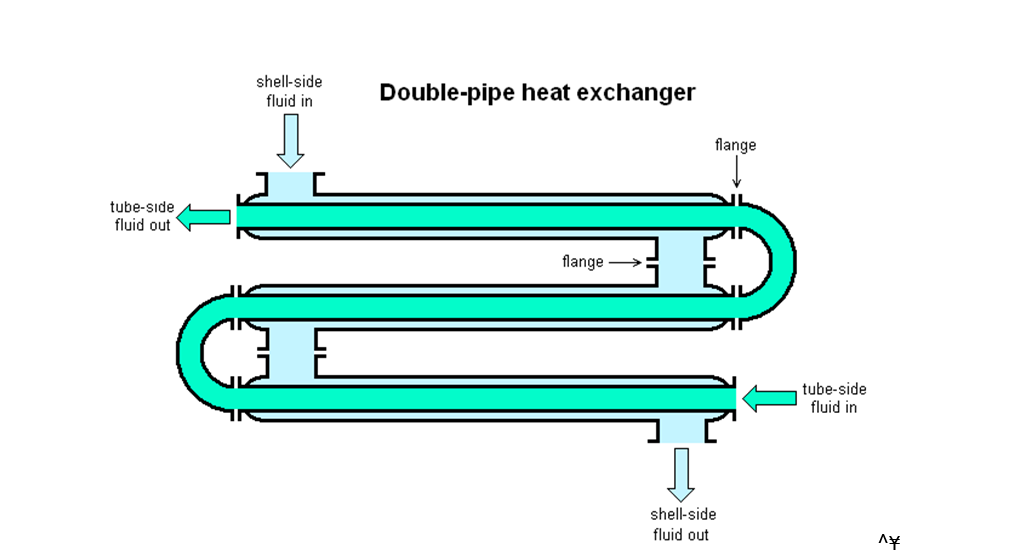

Figure 2 shows the basic schematic of a double-pipe heat exchanger, which features two concentric pipes with two different fluids (at different temperatures) flowing through each of the channels.

Figure 2: Double-pipe heat exchanger. Source: Turbojet/CC BY-SA 4.0

Figure 2: Double-pipe heat exchanger. Source: Turbojet/CC BY-SA 4.0

This basic heat exchanger design operates based on the principles of heat transfer, including conduction and convection. For instance, conduction heat transfer occurs through the solid material that separates the fluids, while convection heat transfer occurs within the fluid as it circulates through the pipes.

As these two fluids flow in the heat exchanger, the hotter fluid loses heat, while the cooler fluid gains heat until the fluids’ temperature reaches thermal equilibrium. The effectiveness of this process depends on factors such as fluid properties, flow rate, surface area and heat exchanger design.

Basic types of heat exchanger designs.

There are various types of heat exchangers, but three common ones are:

#1 Double-pipe heat exchanger

The simplest is the double-pipe heat exchanger, which has been described in the previous section. However, this double-pipe heat exchanger can be categorized according to the type of flow arrangement:

- Parallel-flow heat exchanger

- Counter-flow heat exchanger

In the parallel-flow heat exchanger, the hot fluid and cold fluids enter the heat exchanger at the same end and move in the same direction. In contrast, the counter-flow heat exchangers are designed so that the fluids enter at opposite ends and move in opposite directions.

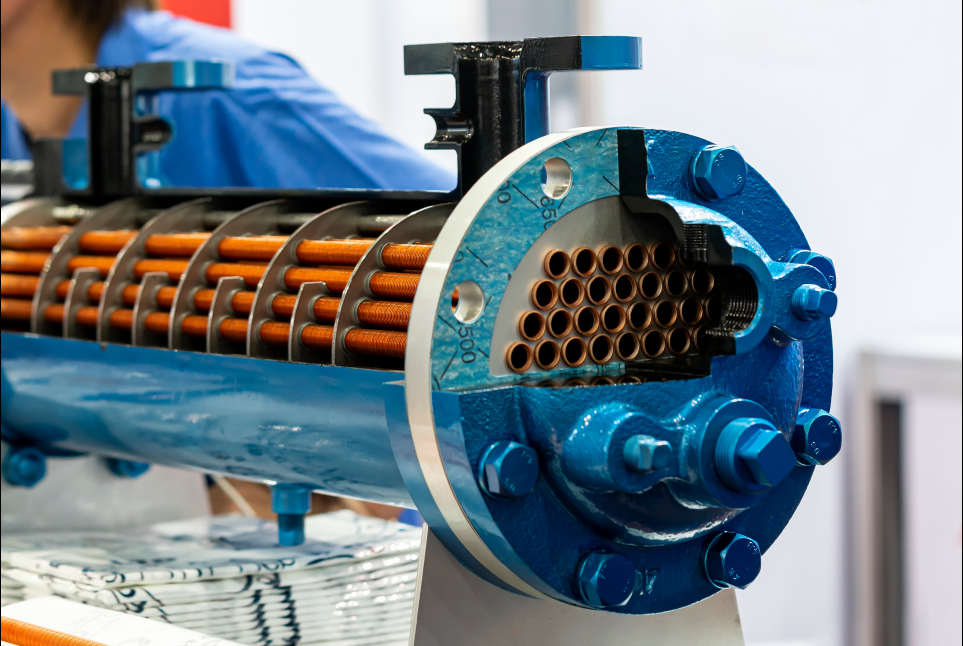

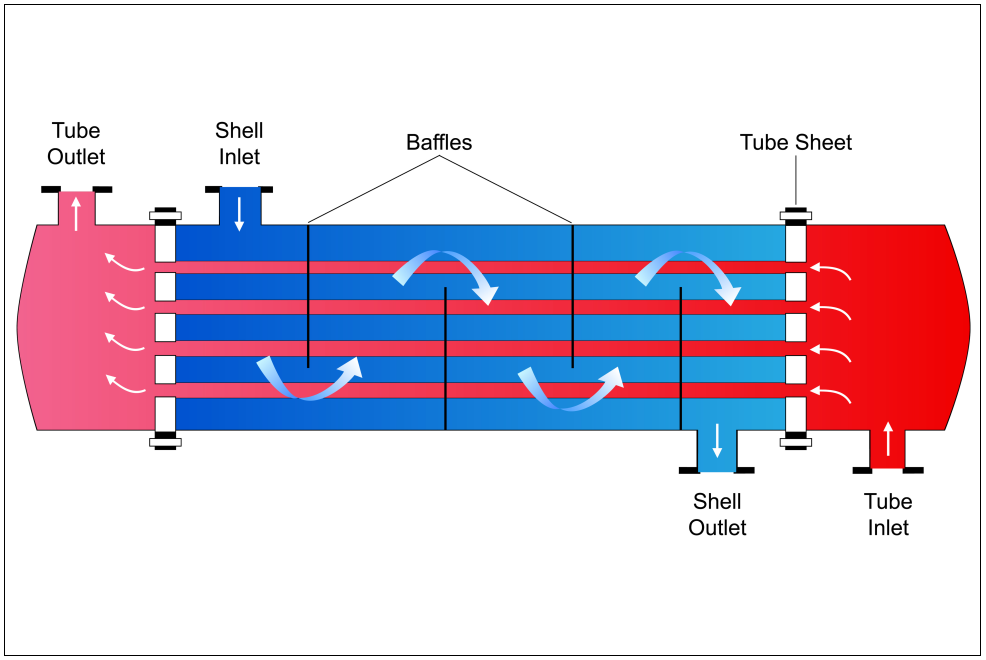

#2 Shell and tube heat exchangers

The shell and tube heat exchanger is the most common type for high-temperature and high-pressure industrial applications. It features a series of tubes packed within a larger shell. The heat transfer process occurs as one of the fluids flows through the tubes while the other flows around them (through the shell).

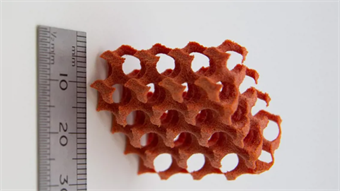

Figure 3: Shell and tube heat exchanger. Source: mrhighsky/Adobe Stock

Figure 3: Shell and tube heat exchanger. Source: mrhighsky/Adobe Stock

Baffles are commonly placed in the shell to provide structural support to the tubes and improve flow disruption, increasing turbulence and enhancing heat transfer. Moreover, the increased heat transfer surface area created by the baffles lengthens the flow path and increases the time the shell-side fluid is in contact with the tubes. This extended contact time facilitates heat transfer.

#3 Plate heat exchangers

The plate heat exchangers consist of thin metal plates stacked together to create a series of channels for the hot and cold fluids to flow through alternately. This unique design provides a large surface area, promoting efficient heat transfer. Plate heat exchangers are commonly used in applications requiring liquid-to-liquid heat exchange, particularly in low- to medium-pressure systems.

Other types of heat exchangers include the printed circuit heat exchanger and air-cooled heat exchangers.

Learn more about the different types of heat exchangers on GlobalSpec.

Basic analysis of heat exchangers

While heat exchangers are commonly used in practice, their desirable operation can only be achieved if they are properly designed or selected to achieve a specified temperature change in a fluid stream of known mass flow rates. Engineers typically design parallel-flow and cross-flow heat exchangers based on several simplifying idealizations, such as modeling them as steady-flow devices and considering axial heat conduction along the tube as negligible. Based on these assumptions, the rate of heat transfer in a heat exchanger can be calculated using:

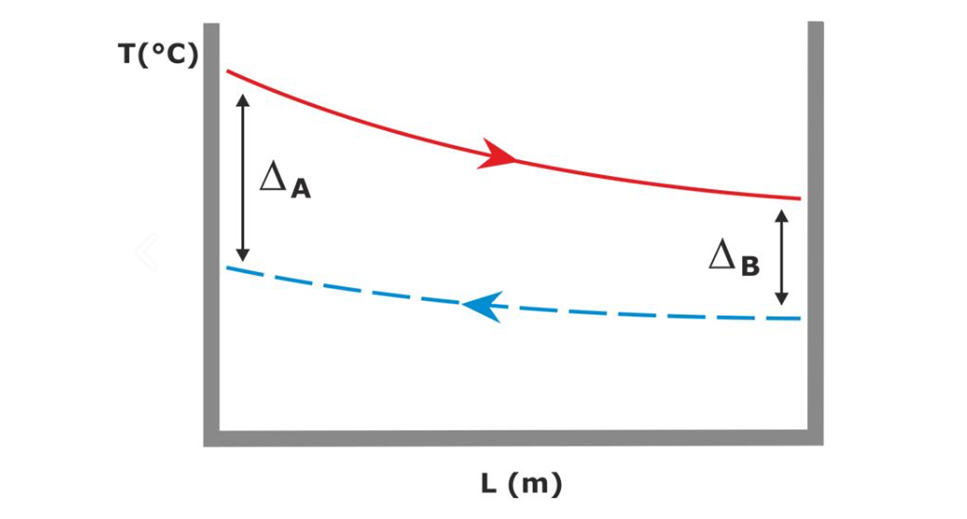

In practice, the temperature difference between the hot and cold fluids varies along the heat exchanger, and it is logarithmic in nature, as shown in Figure 4.

Figure 4: The temperature difference between hot and cold fluids in a counter-flow heat exchanger. Source: Ginotonix/CC BY-SA 4.0

Figure 4: The temperature difference between hot and cold fluids in a counter-flow heat exchanger. Source: Ginotonix/CC BY-SA 4.0

Therefore, engineers typically calculate the average temperature difference between the hot and cold fluids using the log mean temperature difference, which can be calculated using:

Conclusion

While this article presents the basics of heat exchanger designs, there are several other factors that must be considered when choosing a heat exchanger for an application. For instance, engineers also consider the type of working fluid, engineering material, pumping power and efficiency requirements when selecting a heat exchanger for an application. Therefore, it is recommended to reach out to heat exchanger manufacturers to discuss application requirements.