Interactive tool for automotive design engineers

S. Himmelstein | October 21, 2020A new interactive resource tool for automotive design engineers has been launched by e Aluminum Extruders Council (AEC), a trade association dedicated to advancing the use of aluminum extrusion in North America.

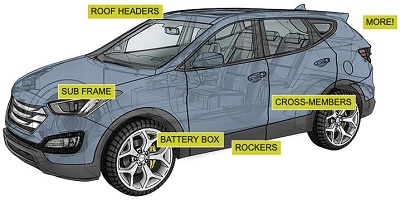

The online AutoSolutions portal provides information on the effective use of aluminum extrusions in various vehicle components, systems and subsystems, and highlights technical details such as alloys, fabrication methods and performance characteristics. As users scroll over an image of a vehicle, a pop-up box appears to  The website offers aluminum extrusion technical details, applications and case examples for automotive industry professionals. Source: AECprovide information on the selected system or component, offering a link to explore deeper into that particular application.

The website offers aluminum extrusion technical details, applications and case examples for automotive industry professionals. Source: AECprovide information on the selected system or component, offering a link to explore deeper into that particular application.

The site offers detailed information on vehicle components including roof headers, battery boxes, sub frames, rockers and cross members. More modules are being developed for the interactive tool designed to assist automotive designers better understand aluminum extrusions and how to effectively employ them in vehicle applications.

"Aluminum extrusions are ideal for helping to remove weight in vehicle design, but they offer so much more," said Mark Butterfield, AEC automotive team chairman and managing director of Magnode, A Shape Corp. Company. "Aluminum extrusions are corrosion resistant with high strength-to-weight ratio and can deliver a part that can be complex, produced to tight tolerances and combines multiple functions to eliminate parts and be easily assembled. And, they are fully recyclable. That combination of attributes has led to an 80% increase in the use of extruded shapes per vehicle since 2012, and we project an additional 40-50% growth in per-vehicle usage over the next five years."